In mineral specimen lab processing, “Assumptions are the origin of all mistakes”. For this reason, only tried and true procedures are applied to our customer specimens. Nevertheless, we are constantly testing new techniques on mineral samples and crystals specifically designed for this purpose, with the goal of improving the quality of our work and the durability of the results. Through collaboration with some of the most advanced manufacturers of products and equipment in the field of the restoration of the arts (where Italy is traditionally a leader), M.C.P. has been able to research new devices and experiment with advanced products, allowing us to develop new proprietary techniques. We also pool knowledge and cross-apply products and tools that are designed for the gemological industry and utilize them when possible in the specimen preparation. The goal of al of this activity is to achieve the best possible result through the use of the most conservative techniques, with special care to natural characteristics of the examples.

We also participate in research done in collaboration with university researchers whenever we can, in an effort to refine our techniques and solve challenging problems, such as the deterioration of species sensitive to light exposure or atmospheric conditions such as humidity, temperature, and gas composition. As well as to refine cleaning and preparation techniques on mineral aggregates in which the main species is extremely soft and cannot come in contact with water, acids, or basic solutions such as soap.

Selenite on halite, specimen 14 cm tall, Saxony, Germany. F.M.I. specimen.

James Elliott photo

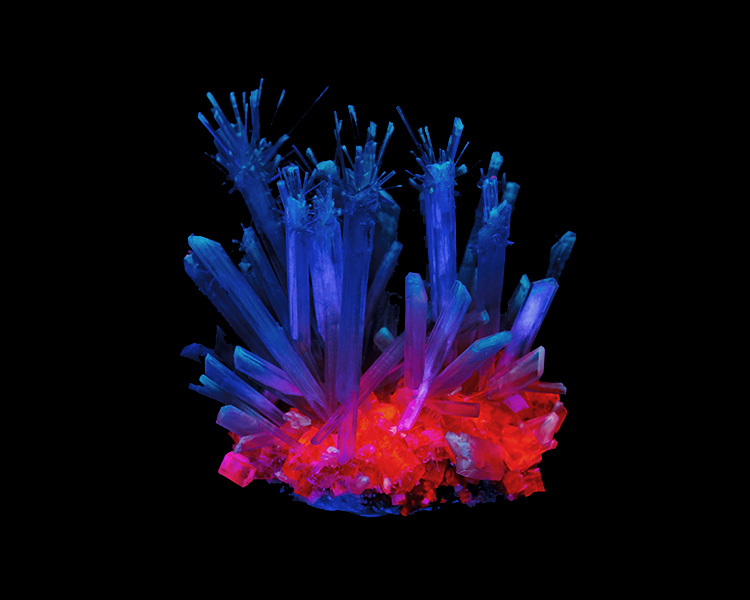

Same specimen as (1), under UV-light (long waves).

James Elliott photo